The Role of Silicon Carbide and Diamond Composites in Electroless Nickel Coatings

The Role of Silicon Carbide and Diamond Composites in Electroless Nickel Coatings

Blog Article

Ensuring the longevity and resilience of metal parts and equipment is a top priority for many industries. Electroless nickel coating stands out as a highly effective method for achieving these goals, offering a uniform, hard, and corrosion-resistant layer through chemical deposition of nickel-phosphorous or nickel-boron alloys. Unlike traditional electroplating, this process does not rely on electrical currents, making it ideal for coating complex shapes and intricate parts.

Incorporating Advanced Additives

To further elevate the capabilities of electroless nickel coatings, nickel platers and metal finishing experts are increasingly turning to silicon carbide and composite diamond additives. These enhancements significantly enhance the hardness, wear resistance, and overall durability of coated components.

Silicon carbide particles, when combined with nickel during deposition, create a composite coating that merges nickel's corrosion resistance with silicon carbide's exceptional hardness and wear resistance. This composite proves invaluable in applications subjected to high abrasion and mechanical stress. Similarly, integrating composite diamond particles into the nickel matrix results in a coating with even greater hardness and wear resistance, perfectly suited for the most demanding industrial environments.

Additional Enhancements

Beyond silicon carbide and composite diamond, other additives further enhance electroless nickel coatings:

- PTFE (Polytetrafluoroethylene): Adding PTFE particles produces a self-lubricating coating that reduces friction, ideal for applications involving moving parts such as machinery and automotive components.

- Boron Nitride: This additive imparts excellent thermal stability and low friction properties, making it perfect for high-temperature applications and components requiring superior lubrication.

- Molybdenum Disulfide: Known for its lubricating properties, molybdenum disulfide reduces wear and friction in metal parts, particularly beneficial in high-load applications.

Applications and Benefits

Electroless nickel coatings find wide application across various metal parts to enhance performance and longevity. Key applications include:

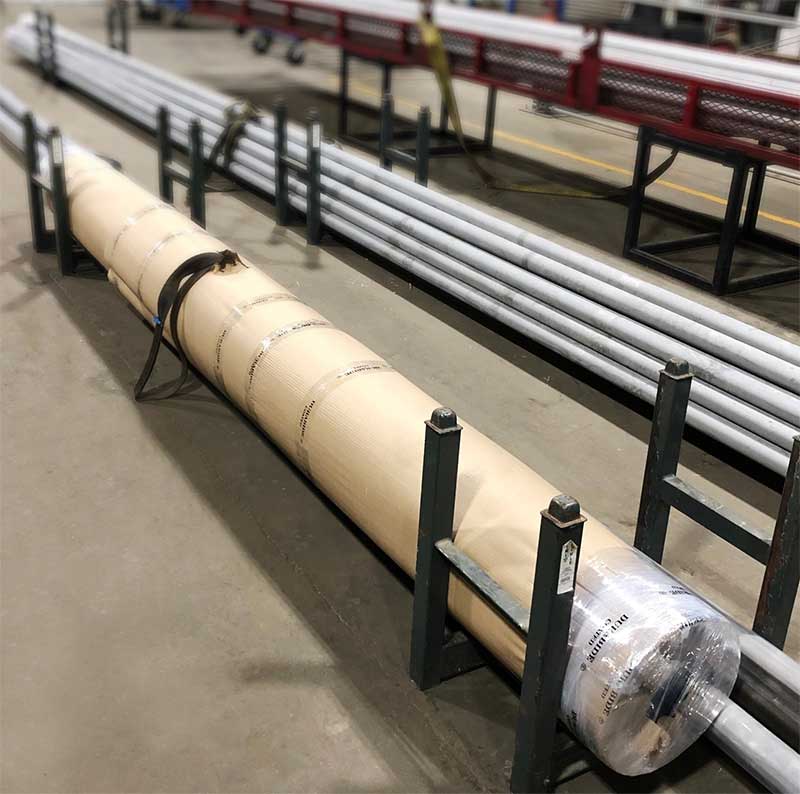

- Brass Tubing: Electroless nickel coating adds an extra layer of protection against wear and corrosion to brass components used in plumbing, electrical connectors, and musical instruments, enhancing their durability in demanding environments. Metal plating for brass is a popular service among metal coaters in Texas, because brass pipes and tubing are commonly used in oil extraction processes.

- Steel Shafts and Bearings: Components used in automotive and industrial machinery benefit significantly from increased hardness and wear resistance provided by electroless nickel coatings, minimizing maintenance requirements and extending service life.

- Aluminum Components: Despite aluminum's inherent corrosion resistance and lightweight properties, electroless nickel coatings enhance hardness, crucial for aerospace and automotive parts where strength and durability are critical.

Corrosion Protection and Beyond

For businesses seeking to enhance the durability of their metal parts, utilizing a corrosion protection coatings service is essential. Companies offering nickel carbide plating service in TX and other areas are at the forefront of this industry, providing advanced coatings that protect against corrosion, wear, and chemical damage. These services are vital for industries ranging from oil and gas to electronics, where equipment longevity and reliability are paramount.

Conclusion

Electroless nickel coating emerges as a robust solution for enhancing the durability and performance of metal components. By leveraging additives such as silicon carbide, composite diamond, PTFE, boron nitride, and molybdenum disulfide, nickel platers can significantly elevate coating properties. From brass tubing to steel shafts and aluminum components, industries benefit from enhanced hardness, wear resistance, and corrosion protection, facilitated by advanced metal finishing services like nickel carbide plating. These innovations are pivotal in maintaining the integrity and functionality of vital components across various industrial sectors.

Report this page